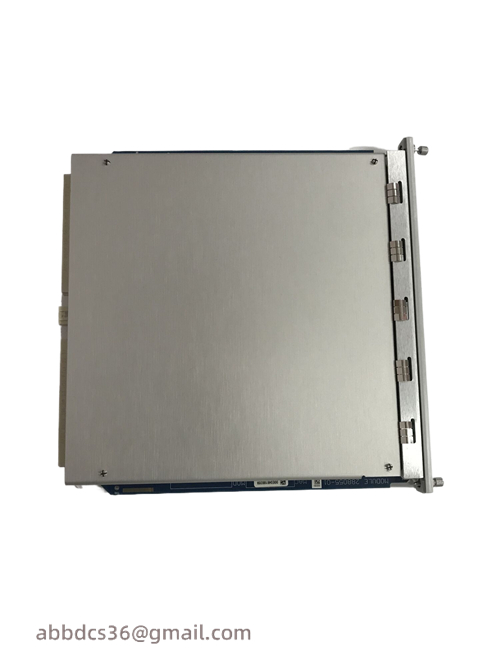

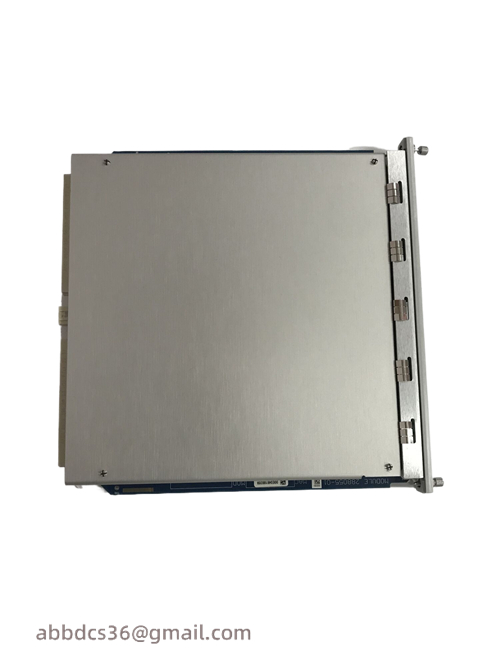

Bently 3500/22M 288055-01 Transient Data Interface Module

Bently 3500/22M 288055-01 Transient Data Interface Module

Product manual:

Bently Nevada 3500/22M 288055-01 Transient Data Interface Module

It is a part of the 3500 series vibration monitoring system, designed specifically for real-time capture and processing of transient data from equipment.

These data mainly include vibration impact, acceleration changes, and other rapidly changing signals, which are helpful for equipment status monitoring, fault diagnosis, and prediction.

Main features:

Model: 3500/22M 288055-01

Function: This module can capture real-time transient data of the device and analyze rapidly fluctuating signals (such as vibration impact, acceleration changes, etc.),

And transmit the data in real-time to the control system or other monitoring modules for fault detection and prediction.

Input/Output: Supports multiple types of sensor inputs, including accelerometers

Speed sensors, vibration sensors, etc. are capable of processing various analog signals.

Data processing and transmission: Transient data is processed through high-speed sampling and real-time processing,

Ensure accurate capture and transmission to the monitoring system for timely analysis and warning.

Compatibility: Compatible with other modules in the 3500 series, able to work with other monitoring modules

Seamless integration of control systems and equipment.

Application areas:

Equipment fault diagnosis: Especially suitable for industrial environments with large equipment vibration or shock fluctuations,

Monitoring of key equipment such as turbines, compressors, pumps, etc. in industries such as electricity, oil and gas, mining, and manufacturing.

Real time status monitoring: By collecting transient data from devices,

Real time feedback on the health status of the equipment, helping engineers detect problems in a timely manner and take preventive measures.

Fault warning and prediction: By monitoring transient data, potential faults can be identified early, reducing unexpected downtime and maintenance costs.

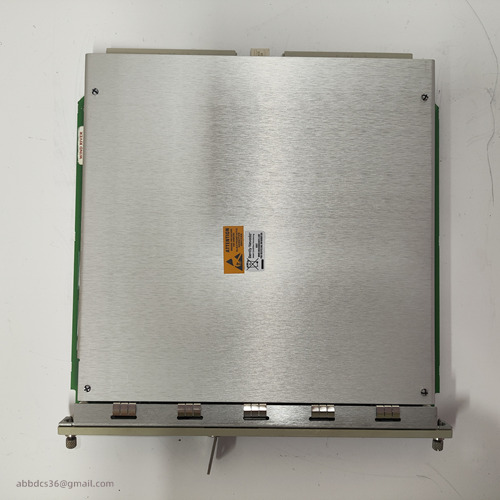

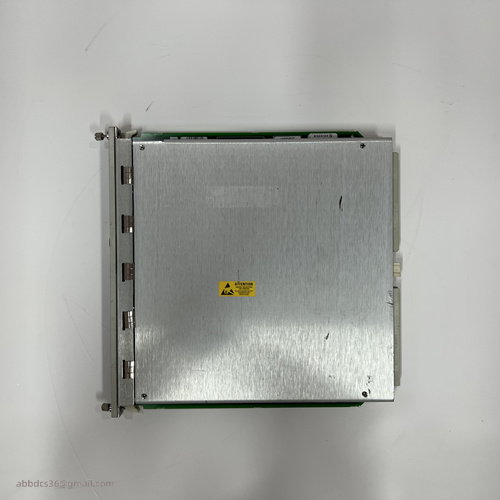

Product details picture:

Bently Nevada 3500/22M 138607-01 Transient Data Interface Module

Bently Nevada 3500/22M, 138607-01A – Transient Data Interface Module