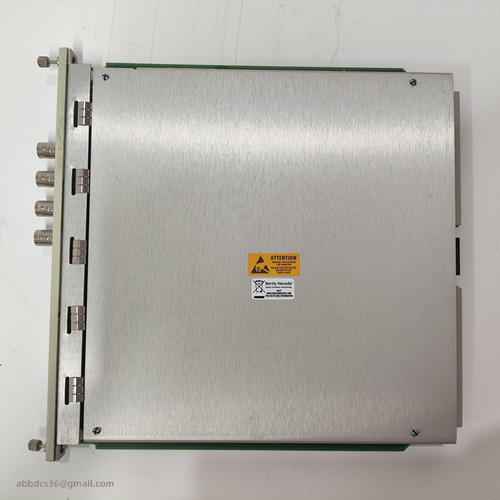

Bently 3500/42M 176449-02 Seismic Monitor

Bently 3500/42M 176449-02 Seismic Monitor

Product manual:

Product Features

Earthquake specific monitoring

Specially designed for detecting vibrations, accelerations, and displacements caused by earthquakes.

Support multiple seismic sensor inputs to meet diverse monitoring needs.

Modular design

Plug in module, seamlessly compatible with the 3500 framework.

Easy to install, replace, and expand the system.

High sensitivity and precision

Built in digital signal processor (DSP) ensures high precision and real-time vibration monitoring.

Support user-defined alarm parameters to accurately distinguish between normal vibration and earthquake events.

Dual alarm function

Provide two levels of alerts, Alert and Danger, for quick response.

Support linkage with device protection system to prevent secondary damage.

Data integration and remote monitoring

Can be integrated with control systems, supports remote monitoring and data recording, and facilitates long-term trend analysis.

Output standard industrial signals, compatible with mainstream automation systems.

LED status display

The module and channel status are displayed in real-time through LED, making it convenient for quick diagnosis and maintenance.

technical specifications

Monitoring channels: 4 independent monitoring channels, each channel can be configured separately.

Supporting sensors:

Earthquake accelerometer

Vibration sensor

Alarm level:

Alert: Indicates device operation deviation.

Danger: Indicates a serious threat of seismic activity.

Input signal: Compatible with analog signal input, supports sensitivity adjustment.

Signal output:

Alarm triggered output

Transmission of vibration monitoring data to the upper computer

Power supply method: Powered by a 3500 frame without the need for a separate external power source.

Environmental adaptability:

Working temperature:- 30 ° C to+65 ° C

Storage temperature:- 40 ° C to+85 ° C

Humidity range: 5% to 95% (without condensation)

Size and Installation: Complies with the 3500 series module size and occupies one slot.

Product details picture:

Bently Nevada 3500/42M Monitor Module for Enhanced Machine Monitoring

BENTLY 3500/42M 128229-01 Small Card, Vibration Monitoring Module