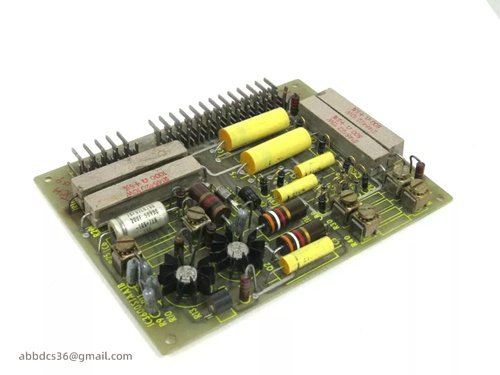

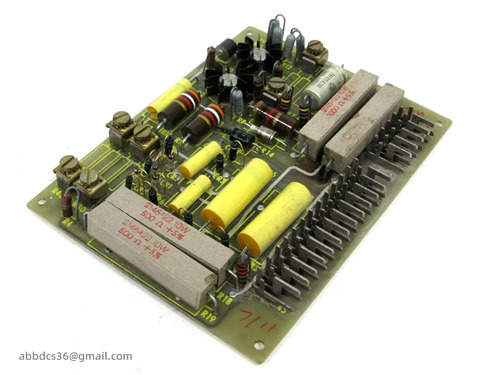

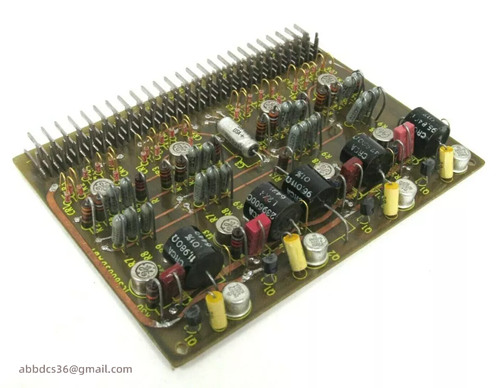

IC3600SVZB1 Computer Adjustment Card

IC3600SVZB1 Computer Adjustment Card

Product manual:

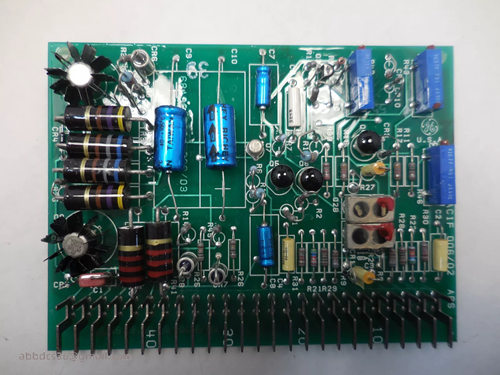

IC3600SVZB1 is a computer control card in the GE gas turbine control system,

It belongs to the Mark series control module. It is used to regulate and control various important parameters of gas turbines,

Ensure the efficient and safe operation of gas turbines.

Function and Features

Regulation and control:

Mainly responsible for real-time adjustment of gas turbine operation, processing data from sensors,

Adjust key parameters such as speed, temperature, and pressure of the gas turbine.

Implement operations such as start-up, load regulation, and shutdown to ensure that the gas turbine operates at its optimal state.

Real time data processing:

Provide real-time monitoring and analysis of various operational data of gas turbines,

Capable of automatically adjusting control strategies based on data to optimize the working state of gas turbines.

safeguard:

Equipped with multiple safety protection functions, including fault protection against overspeed, overheating, overvoltage, etc,

Being able to respond quickly in case of abnormalities and protect equipment from damage.

technical specifications

Input power supply: usually 24V DC (depending on device requirements).

Input signal: Supports analog signals (such as 4-20mA, 0-10V) and digital signal input and output.

Working temperature: Designed to operate within a wide temperature range, typically from -40 ° C to+70 ° C.

application

Gas turbine control system: used for precise regulation and control of gas turbines.

Energy and power generation industry: widely used in power stations and gas-fired power generation equipment,

Ensure the efficient operation of gas turbines.

maintain

Regularly check the power supply and input signals to ensure that the equipment is working properly, and check if the protection mechanism is working properly to avoid potential faults.

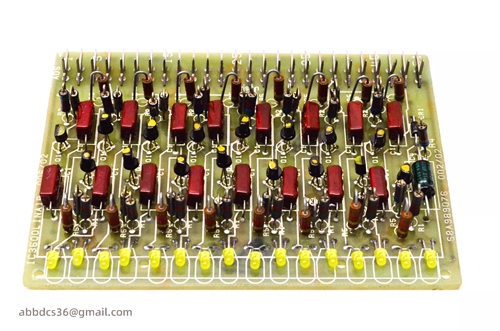

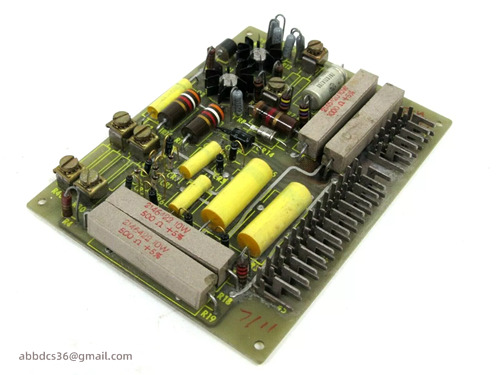

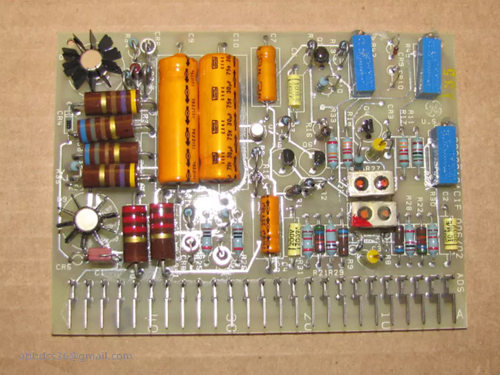

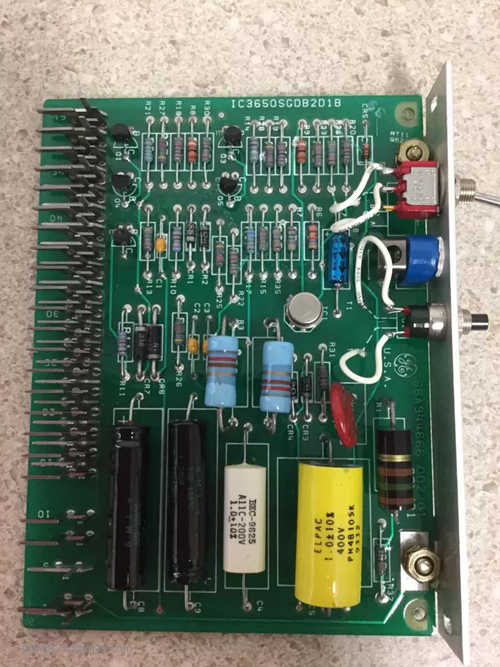

Product details picture:

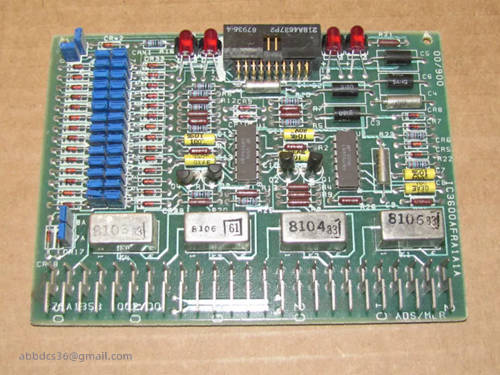

General Electric IS230SNRTH2A – High-Performance Control Circuit Board