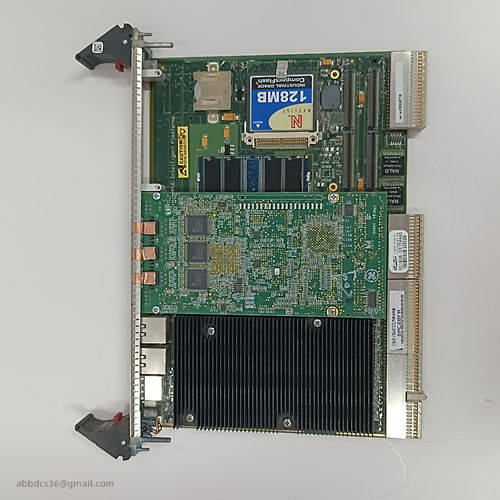

GE IS220PTURH1A Turbogenerator

GE IS220PTURH1A Turbogenerator

Product manual:

GE IS220PTURH1A is a module in the GE Mark VIe series designed for turbine control, primarily used in the power generation and industrial drive sectors, particularly for gas turbine control and monitoring.

Main features:

Core functions:

Specially designed for gas turbine control, responsible for monitoring and controlling the start-up, operation, shutdown, and other processes of gas turbines.

Provide multiple input and output interfaces, capable of real-time collection of temperature, pressure, and other parameters of the turbine

Key data such as rotational speed, and adjust combustion, load, and other parameters according to control strategies.

Performance and Communication:

Input/output interface: Supports multiple analog and digital inputs and outputs, suitable for complex monitoring requirements of turbines.

Communication protocol: Supports integration with other GE control system modules

(such as IS220, Mark VIe, etc.) exchange data through Ethernet or industrial protocols to ensure system integration.

Real time monitoring: capable of obtaining real-time operation status and fault information of the turbine, conducting self diagnosis and maintenance reminders.

Reliability and Safety:

High reliability design, suitable for harsh industrial environments, ensuring that the turbine operates at high temperatures

Stable operation under high pressure conditions.

Support redundant design, enhance the system’s fault tolerance, and ensure the continuity and safety of critical tasks.

Scalability and compatibility:

It can be integrated with other modules in the GE Mark VIe series, such as input/output modules, control modules, etc., to build a complete turbine control system.

Support integration with SCADA systems to achieve remote monitoring and data collection.

Application scenarios:

Gas turbine power generation: used for starting, monitoring, and controlling gas turbines to ensure efficient and stable power generation.

Industrial drive system: applied to industrial equipment drive systems, providing precise speed and load regulation.

Product details picture:

General Electric IS220PTURH1A – Advanced Turbine Control Module