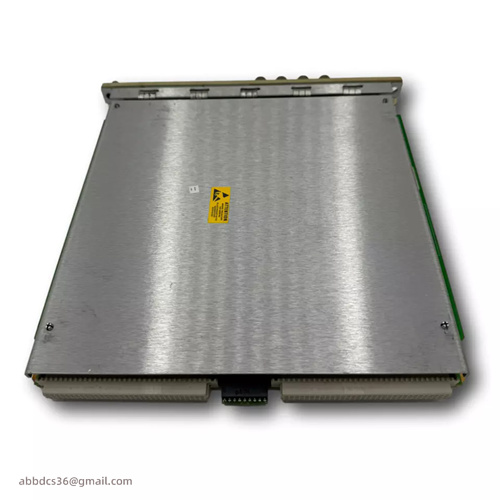

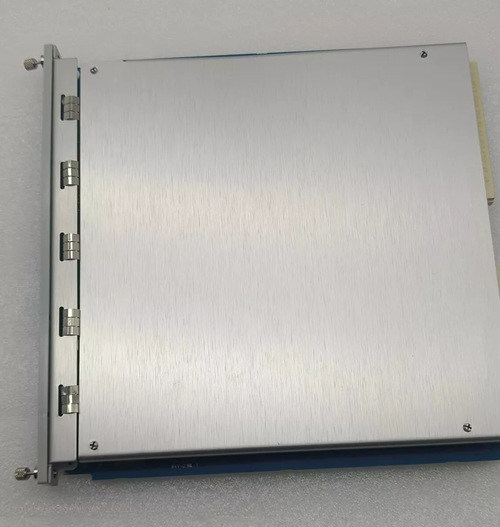

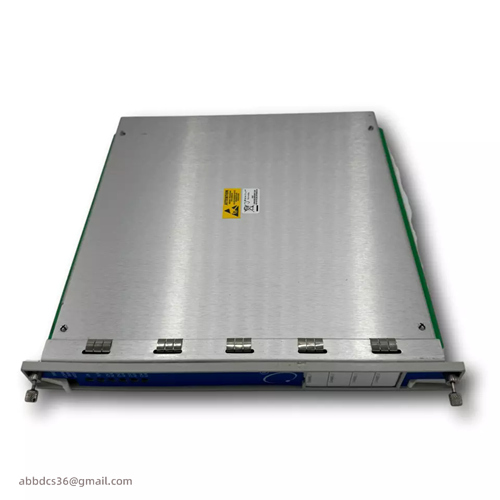

Bently 3500/42-01-00 Seismic Monitor

Bently 3500/42-01-00 Seismic Monitor

Product manual:

The Bently Nevada 3500/42-01-00 Seismic Monitor is a module designed specifically for monitoring the effects of seismic vibrations and is a key component of the 3500 series. It can accurately collect and analyze vibration data caused by earthquakes, help users monitor the operating status of equipment in industrial environments in real time, and take protective measures when necessary.

Product Features

Seismic vibration monitoring

Specially designed to detect the impact of earthquakes or geological activities on equipment.

Monitor the response vibration amplitude and frequency of the monitoring equipment.

Modular integration

Plug in design seamlessly integrates with the 3500 series framework.

Easy to expand, configure, and maintain.

High sensitivity sensor support

Supports multiple high-precision seismic sensor inputs.

Provide reliable data collection and processing capabilities.

Alarm and protection functions

Provide dual level alerts: Alert and Danger.

Can trigger protective actions, such as shutting down the device or sending a remote alarm signal.

Real time data processing

Built in high-performance digital signal processing (DSP) ensures real-time and accurate monitoring data.

Support user-defined alarm thresholds and data processing logic.

Status indication and diagnosis

Equipped with LED status light display module and channel status, it facilitates quick diagnosis of faults.

technical specifications

Monitoring channel: Supports multiple sensor inputs, with each channel processing independently.

Supported sensor types:

Earthquake accelerometer

Vibration sensor

Alarm function:

Dual level alarm: Alert and Danger.

The alarm output signal can be linked with the protection system.

Signal processing:

Built in digital filtering, supporting customized bandwidth and frequency range.

Data output:

Support real-time data transmission to monitoring systems or recording devices.

Power supply requirement: Powered through a 3500 frame.

Work environment:

Working temperature:- 30 ° C to+65 ° C

Humidity: 5% to 95% (without condensation)

Installation method: Plug in type, occupying one slot in a 3500 rack.

Module size: Complies with 3500 standard specifications.