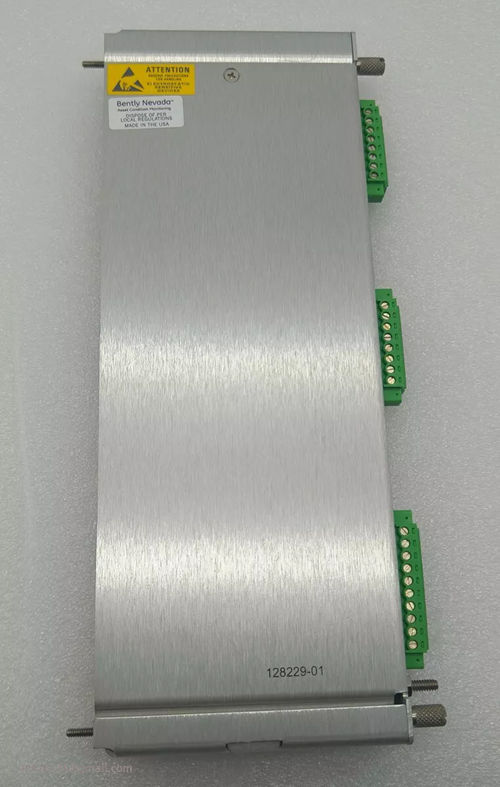

Bently 3500/42M 135489-01 Transient Data Interface

Bently Transient Data Interface

Product manual:

Product Features

High performance transient data capture

Support real-time collection and processing of transient vibration data.

Used to analyze the characteristics of the start-up, shutdown process, and sudden failures of mechanical equipment.

Multi channel input

Provide multiple monitoring channels to simultaneously capture transient signals from multiple points.

Supports multiple types of vibration sensors and data input.

High precision signal processing

Built in digital signal processor (DSP), supporting functions such as signal filtering and spectrum analysis.

Provide data processing and storage capabilities for subsequent analysis.

Alarm function

Equipped with dual level alarms (Alert and Danger), real-time monitoring of equipment status changes.

It can be linked with other 3500 modules to achieve protection and alarm functions.

Data Integration and Visualization

Can output captured data to the upper computer or monitoring system for in-depth analysis.

Support integration with Bently Nevada System 1 software for trend analysis and event recording.

technical specifications

Number of monitoring channels: 4 independent channels, each channel can be configured separately.

Input type: Supports signal input such as vibration, displacement, velocity, acceleration, etc.

Signal processing: Built in digital signal processor for signal acquisition, filtering, and feature extraction.

Transient event recording: supports recording abnormal events that occur during startup, shutdown, or operation.3500/42M

Alarm mechanism:

Alert: Used to indicate abnormal trends.

Danger: Used to indicate serious abnormalities and trigger protective actions.

Output interface: Supports outputting data to SCADA or DCS systems through communication modules.

Power supply method: Powered by 3500 racks.

Environmental adaptability:

Working temperature:- 30 ° C to+65 ° C

Humidity range: 5% to 95% (without condensation).